What we do

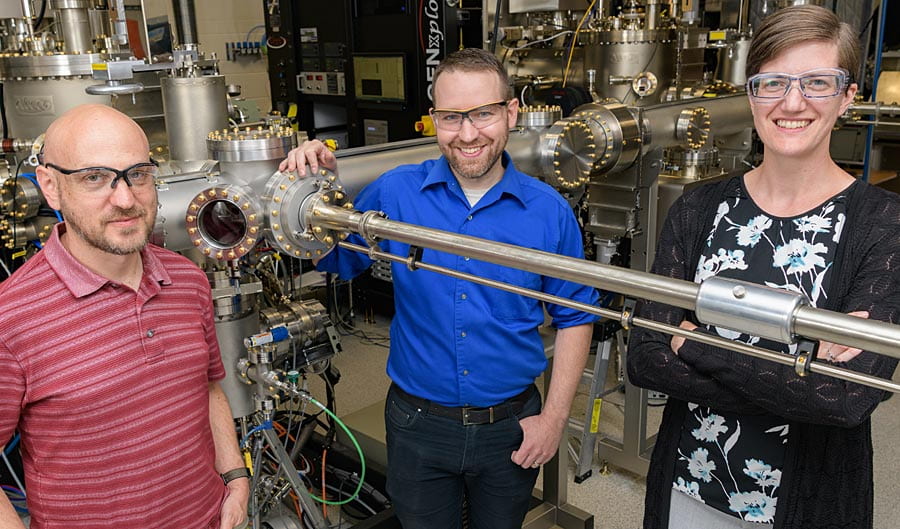

The University of Delaware Materials Growth Facility (MGF) primary objective is to provide the infrastructure, equipment, and staff support necessary to enable existing faculty, new faculty, and academic and corporate partners to undertake competitive research and development in the growing number of materials, science, and engineering fields.

Capabilities

Our III-V molecular beam epitaxy (MBE), chalcogenide MBE, and magnetic sputtering system include many unique capabilities.

Services

Staff

Materials Research

Core Partnerships

Advanced Materials Characterization Lab

Keck Center for Advanced Microscopy & Microanalysis

Nanofabrication Facility

Leading the Way

Contact Us

If you need further assistance or are have a specific request, please fill out the form below and we will get back to you shortly.