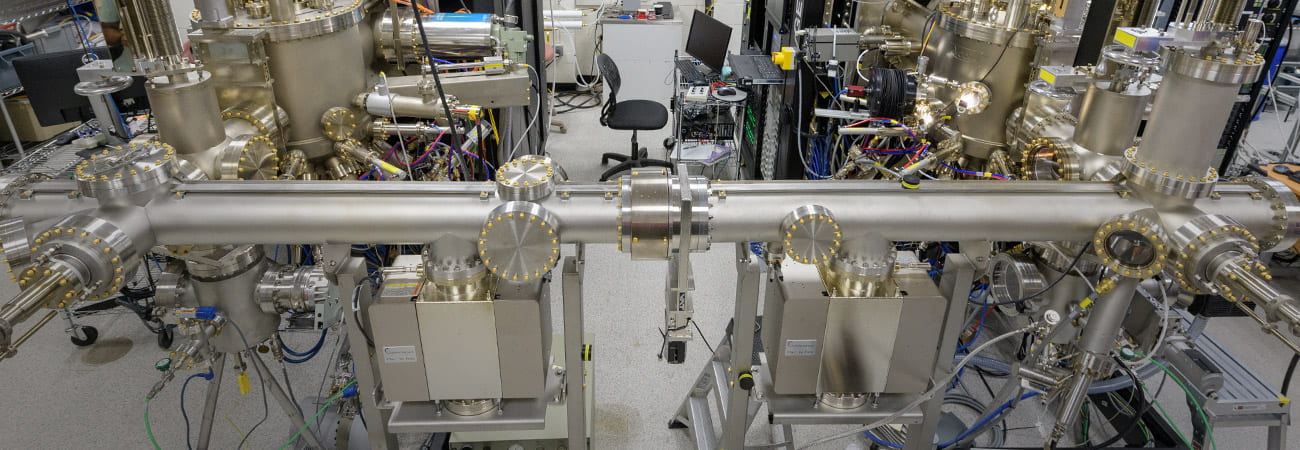

Molecular beam epitaxy reactors (MBE)

MBE involves the thermal evaporation or sublimation of ultra high-purity elements in a UHV chamber. Source temperatures control beam fluxes (thus growth rate) and high speed shutters control alloy combinations (e.g. GaAs, Be-doped AlGaAs, Bi2Se3, etc.). Atomic/molecular beams are incident on a heated crystalline substrate where material growth occurs, with atomically precise control of material composition and interface abruptness.

To maximize sample quality and purity, both MBEs include intro chamber out-gassing of substrates at 200 °C for 12 hours, ionization pumps and a cryogenic pump, and source material up to 7N5 (99.999995%) purity.

Our III-V MBE (Apollo) features

- Standard III-V source materials (gallium, indium, aluminum, arsenic, antimony)

- Electronic doping sources (beryllium, tellurium, high-flux silicon)

- Bismuth and two rare earth sources (erbium, terbium)

- BandiT band-edge thermometry and thermocouple feedback for precise control of substrate temperature

- Atomic hydrogen beam cleaning

- Substrate heating up to 1200 °C (sample rotation up to 60 rpm)

- Sample size: small pieces to 3″ wafers

- In-situ monitoring: pyrometry, RHEED, RGA (to 100 AMU), chamber and BFM ionization gauges

- Load lock sample out-gassing (200 °C)

- Recipe driven

Our chalcogenide MBE (Artemis) features

- Topological insulators source materials (bismuth, indium, antimony, selenium, tellurium)

- Electron beam evaporator for high-temperature materials (tungsten, molybdenum, tantalum, niobium, zirconium)

- Low-flux gallium capping source

- Substrate heating up to 1200 °C (sample rotation up to 60 rpm)

- Sample size: small pieces to 3″ wafers

- In-situ monitoring: RHEED, RGA (to 100 AMU), chamber and BFM ionization gauges

- Load lock sample out-gassing (200 °C)

- Recipe driven

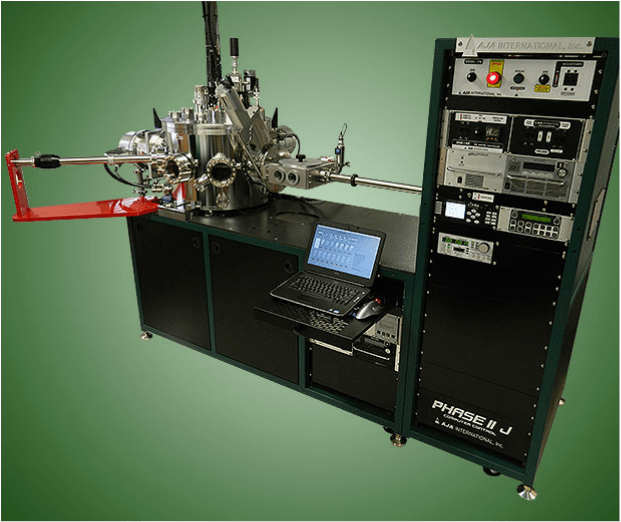

Magnetic sputtering

OUR UHV MAGNETIC SPUTTERING SYSTEM (HEPHAESTUS) FEATURES

- A wide range of source targets (metallic, dielectric, and precious metal)

- Three high-purity gas controllers (argon, nitrogen, oxygen)

- Six magnetrons (three with high strength fields for magnetic target materials)

- Off-axis capability for one magnetron (for deposition of MgO based magnetic tunnel junctions)

- High temperature substrate heater

Contact Us

If you need further assistance or are have a specific request, please fill out the form below and we will get back to you shortly.